Product information

- Category: PES Membrane Cartridge Filter

- Product series: PSguard®

- Product URL: ...

PSguard® Pariticle Reduction Cartridge Filter

The PSguard® filter cartridge is an absolute rated, pleated polyethersulfone (PES) membrane filter designed to provide greater bacteria and removes particles at high flow rates and extremely low pressure drops. It offers the greatest assurance of filtration performance stability and service life for controlling contaminants in demanding environments. PSguard® Filter media is created by a patented process that produces an outstanding polyethersulfone membrane that is inherently hydrophilic. PSguard® membranes are highly durable.

PSguard® EfficiencyPSguard® filter cartridges combine a high dirt holding capacity, protective abilities and extremely high flow rates, These cartridges are easy to clean for an efficient regeneration if necessary.

PSguard® User Manual⚠ Warning! This Section Is Under Development.

PSguard® filter cartridges user manual is available at www.vanguard.com.bd/ecodocs for your ready download. This eco approach from our side as a contribution to reserve the environment.

Features and BenefitsPSguard® Polyethersulfone filter cartridges may be used as either prefilter or final filters. PSguard® filters are most appropriate for use when high efficiency filtration and economy are crucial.

Common industries that use PSguard® filters include:ASTM F838-05 Challenge: 0.2 µm, 0.45 µm >107 cfu/cm2 Brevundimonas diminuta and meet the FDA definition of a sterilizing grade filter.

Materials of ConstructionFilter Media: Polyethersulfone (PES) Upstream Support: Polypropylene Downstream Support: Polypropylene Core/Outer Guard: Polypropylene End Cap: Polypropylene Sealing Method: Thermal Bonding O-ring/Gasket Seal: Silicone PSguard® filters are manufactured in conformance to cGMP. All materials of construction listed above are FDA approved for food contact use per 21 CFR 177. PSguard® filters meet the requirements as specified in the current USP Class VI plastics, cytotoxicity and pyrogenicity tests. No binders, adhesives or surfactants are used in its construction. The filters comply with European Commission Directive 2002/72/EC and subsequent amendments up to 2008/39/EC and Commission Regulation (EU) No 10/2011.

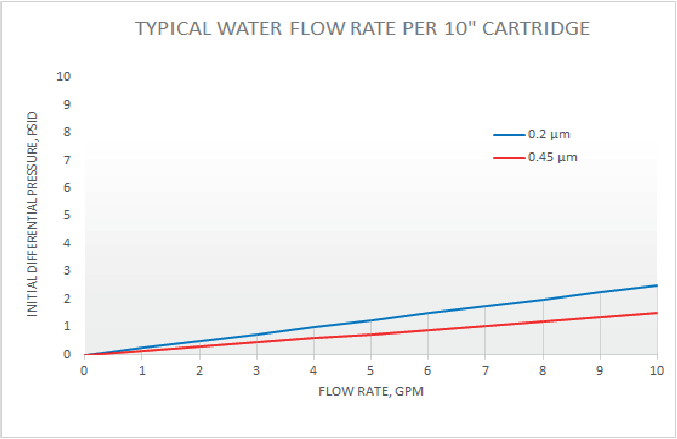

Filtration RatingsPore Sizes:0.2 and 0.45 µm

Cartridge Dimensions

Diameter: 2.75” (7cm)

Lengths: 10”, 20”, 30”, 40” (25cm, 50cm, 75cm, 100cm)

Δp 80 psi @ 32 °F to 100 °F (Δp 5,5 bar @ 0 °C to 38 °C)

Δp 60 psi @ 150 °F (Δp 4,1 bar @ 66 °C)

Δp 30 psi @ 180 °F (Δp 2,1 bar @ 82 °C)

Steam-in-place (SIP):

Saturated steam @ 121-125 °C, 30-60 minutes.

[15 psi (1 bar) to 30 psi (2 bar), 30-60 minutes]

Autoclave: 121-135 °C, 30-60 minutes.

PSguard® cartridges are capable of repeated sterilization cycles. For applications requiring autoclave/SIP, a stainless steel reinforcement ring must be ordered. See “Reinforcement Ring Option” within “Ordering Information”.

please check into the catalogue.